Oil leakage from the turbocharger: causes and remedies.

Most often turbo owners come to us and our colleagues with the words “turbo’s leaking oil, how much will it cost to fix, is there a good used one? Then some variant is chosen according to the text or a plug is put. But in fact, the reason for oil leakage in most cases is not a turbocharger but its wrong installation or improper engine maintenance and operation. To understand what causes a “turbo to leak oil” let’s look at the following points:

- Oil inside the turbocharger

- Seals

- Compressor inlet/outlet oil

- Compressor outlet oil

- Turbine outlet oil

Lube oil inside the cylinder

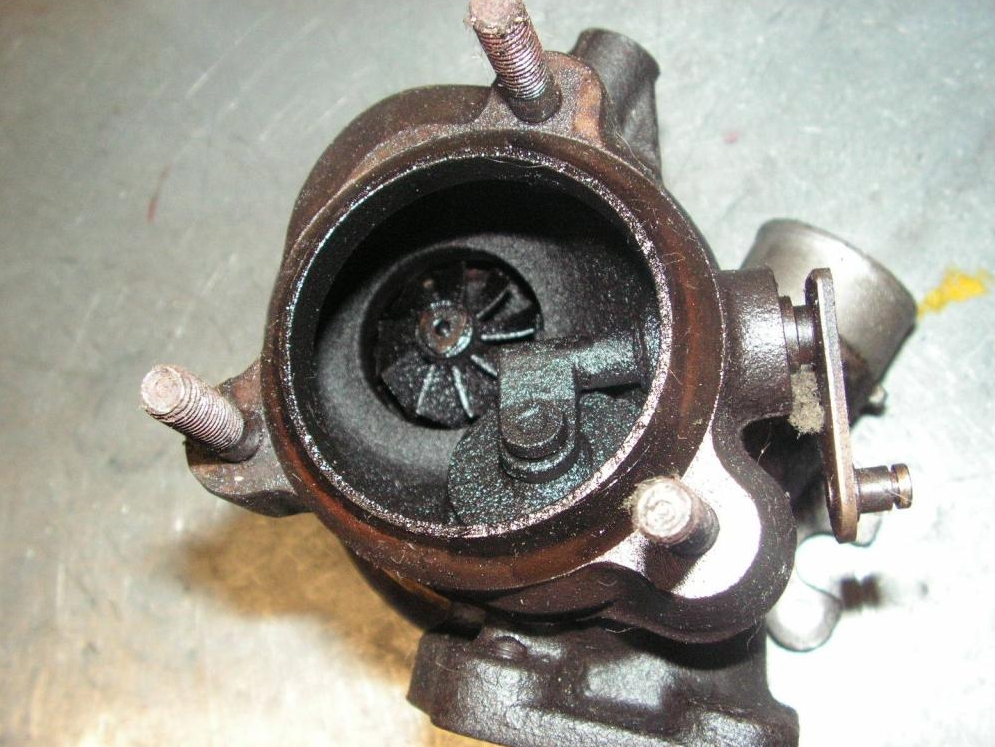

The oil is fed under pressure into the turbocharger bearing housing via a pressure line. On flowing through the bearings at high speed the oil is mixed with the air (crankcase gases). At the outlet of the bearings, the oil mixed with air is already a kind of foam which by gravity first flows down the bearing housing of the turbocharger, and then through the drain line into the engine oil sump. If there is an obstacle in its way it will start to collect in the housing. When the level of oil foam exceeds the level of the seals, oil will begin to flow into the turbine and compressor wheel housings (hot and cold volute) through the gap in the sealing ring.

Seals

The most common misconception of a turbocharger is the purpose of the seals on the sides of the turbine and compressor wheels. The main purpose of these seals is to prevent high pressure gases from flowing into the turbocharger housing and then into the crankcase. The fact that these seals keep oil out of the turbine and compressor housings is secondary. Some turbochargers are even manufactured without seals on the turbine wheel side. In almost all cases oil leakage from the turbocharger is not due to seal failure, although there are exceptions to this rule.

Oil in compressor inlet/outlet

Some ‘leaks’ are caused by the air filter. In an air filter (wet filter) that is already contaminated with oil or has insufficient capacity, air passing through it at high velocity can trap oil droplets and carry them into the compressor housing. This “leakage” can only be observed at the compressor outlet and to fix it either the oil in the filter has to be changed or the filter has to be replaced with another one.

Oil at the compressor outlet

A dry type air filter, after prolonged operation, becomes clogged with dust particles, its resistance increases and consequently the pressure drop across it increases. A small vacuum occurs at the compressor inlet. This vacuum does not affect oil leakage when the engine is running at medium or high loads, because there is excess pressure behind the compressor wheel. When the engine is running at idle speed or under low loads, a vacuum is not only generated at the compressor inlet, but also at the compressor outlet. If this condition persists for a while oil will be sucked out of the turbocharger bearing housing and flow into the engine intake manifold. The solution to such a problem is fairly straightforward. You can either install a sensor between the air filter and the turbocharger that will indicate when you need to change the filter, or you can have the filter changed as specified by the car manufacturer.

Oil at the turbo outlet

Usually, oil leakage at the turbine outlet is an indication of problems in the drainage system. Something is causing the oil foam to rise above the level of the seals. It must be ensured that the drain line is in the upright position (a maximum of 35 degrees from the upright position is allowed) and that it has no bends in which oil can collect. It must also be ensured that the drain line is connected to the engine in a position that does not create additional resistance to oil flow and is above the oil level in the crankcase.

Turbocompressor operating rules

The turbocharger operates under severe conditions: high exhaust gas temperatures (up to 1050°C) and high shaft speeds (up to 280,000 rpm). The oil fed to the turbocharger for lubrication and cooling is drawn from the engine oil system and must always be clean and in accordance with the engine manufacturer’s requirements. After starting, allow the engine to idle for approx. 1 minute. This will allow the oil pressure in the lubrication system to rise to operating pressure and the oil to reach the turbocharger bearings. Before switching off the engine, you should also allow it to idle for a few minutes (1-3) to allow the turbocharger parts to cool down.

Factors affecting the service life of the turbocharger (turbine).

An analysis of turbocharger damage shows that around 40% of damage is caused by foreign bodies hitting the blades of the compressor or turbine wheel. A further 40% of the damage is caused by a faulty lubrication system. The remaining 20 % of damage is due to other causes.

Foreign objects that often fall on the turbine wheel blades include: broken off parts of valves and combustion chamber; improperly installed gasket (parts of the gasket may come off and fall into the exhaust manifold); bolts, nuts and washers that fall into the exhaust manifold when replacing the turbocharger; broken off parts of the engine’s pistons. All of these objects, even if insignificant in size, cause serious damage to the turbine wheel.

Damage to the compressor wheel from foreign objects is less frequent than damage to the turbine wheel. Foreign objects that can get on the compressor wheel include: elements of the air filter; pieces of rubber or reinforcing wire that have come off the intake ports; and bolts, nuts and washers that have been caught in the intake when replacing the turbocharger.

There can be several faults in the lubrication system that cause damage to the turbocharger. The most common is a deposit in the pipes that carry oil to and from the turbocharger. These deposits greatly reduce the flow area of the pipework and sometimes completely block the pipework. For proper operation of the turbocharger it is essential that the manufacturer’s specified amount of oil is supplied to the turbocharger bearings under severe operating conditions. The oil must always pass through a filter before it is supplied to the bearings. With a constant supply of clean oil in the required quantities, the turbocharger bearings can run for thousands of hours without noticeable wear.

Damage to the turbocharger can also be caused by elevated exhaust temperatures when the machine is operated at high altitudes. Any engine that is operated at temperatures close to the limit at sea level will exceed these temperatures at an altitude of 1500 m above sea level. Also operating at such altitudes may cause the turbocharger’s maximum shaft speed to be exceeded. It is therefore necessary to modify the fuel system in accordance with the manufacturer’s requirements. In addition, the increase in the exhaust gas temperature is significantly affected by: late ignition, poor mixture and late injection timing.

Increased inlet resistance, which may be caused by an air filter, damaged connections or insufficiently dimensioned fittings, reduces the amount of air that enters the cylinders and increases the temperature of the exhaust gases. Increased intake resistance and operation at high altitudes can lead to damage to the turbine wheel housing and even to damage to the turbine wheel itself due to high temperatures.

If the air filter is not changed as required by the manufacturer, there is a high risk of dirt deposits in the compressor wheel housing, resulting in reduced air flow to the cylinders and further overheating. Also loose gaskets in the intake and exhaust manifold lead to reduced air supply.

Sometimes the turbocharger connections to the intake and exhaust manifolds are made in such a way that expansion of the exhaust manifold and other parts connected to the turbocharger cause high loads to be placed on the turbocharger components. These loads can cause the turbine and compressor wheel housings to change dimensions such that the wheels start to rub against the housings. Insufficiently rigid mounting of the turbocharger to the engine, which cannot prevent excessive vibration of the turbocharger, can also cause distortion of the turbocharger components and lead to breakdowns.

Turbocompressor damage can be virtually eliminated by keeping foreign bodies away from the turbine and compressor blades, exceeding the allowable turbocharger operating temperatures and by ensuring that the turbocharger is supplied with the correct amount of quality oil.